3D Printing Explained: Building the Future Layer by Layer

Imagine a world where you can conjure physical objects from your wildest dreams with the ease of printing a document. Welcome to the enchanting realm of 3D printing, where imagination meets reality, layer by intricate layer. The technology has been a topic of discussion for a while, but in recent years has become reality, with considerable potential in the future. In this article, we’ll delve deep into the fascinating world of 3D printing—its history, the intricate process behind it, and a glimpse into what the future holds for this revolutionary technology.

The Fascination of 3D Printing

At first glance, 3D printing might seem like magic, and in many ways, it is. It’s the wizardry that allows us to transform digital designs into tangible objects, from a coffee cup to the components of an entire building, all with the precision of master craftsmanship. From producing custom prosthetics to creating intricate architectural models, 3D printing empowers us to create nearly anything. The potential real-world applications are nearly limitless, and the market could reach over $40 billion by 2026.

Unearthing the History: A Journey Through Time

To fully understand 3D printing, it is important to look at its history. The roots of this technology reach into the 1980s when pioneers like Chuck Hull, the father of Stereolithography (SLA), began exploring the possibilities of layer-by-layer additive manufacturing. However, these early endeavours were confined to industrial and prototyping applications, far from the homes and garages of everyday makers.

It wasn’t until the early 21st century that 3D printing began to capture public imagination. As costs decreased and accessibility increased, enthusiasts, inventors, and hobbyists ventured into the realm of 3D printing. Desktop 3D printers became available, opening doors to a new era of creativity. As people tinkered, printed, and shared their creations, a groundswell of innovation emerged.

Demystifying the Process: How 3D Printing Works

There are several different 3D printing processes, and many new approaches are being considered and developed. Let’s take a look at how a 3D printing procedure usually works:

1. Digital Design

The journey begins with a digital 3D model. This can be crafted from scratch using computer-aided design (CAD) software or generated from 3D scans of existing objects.

2. Slicing

The digital model is sliced into thousands of ultra-thin horizontal layers, creating a virtual blueprint for the 3D printer to follow.

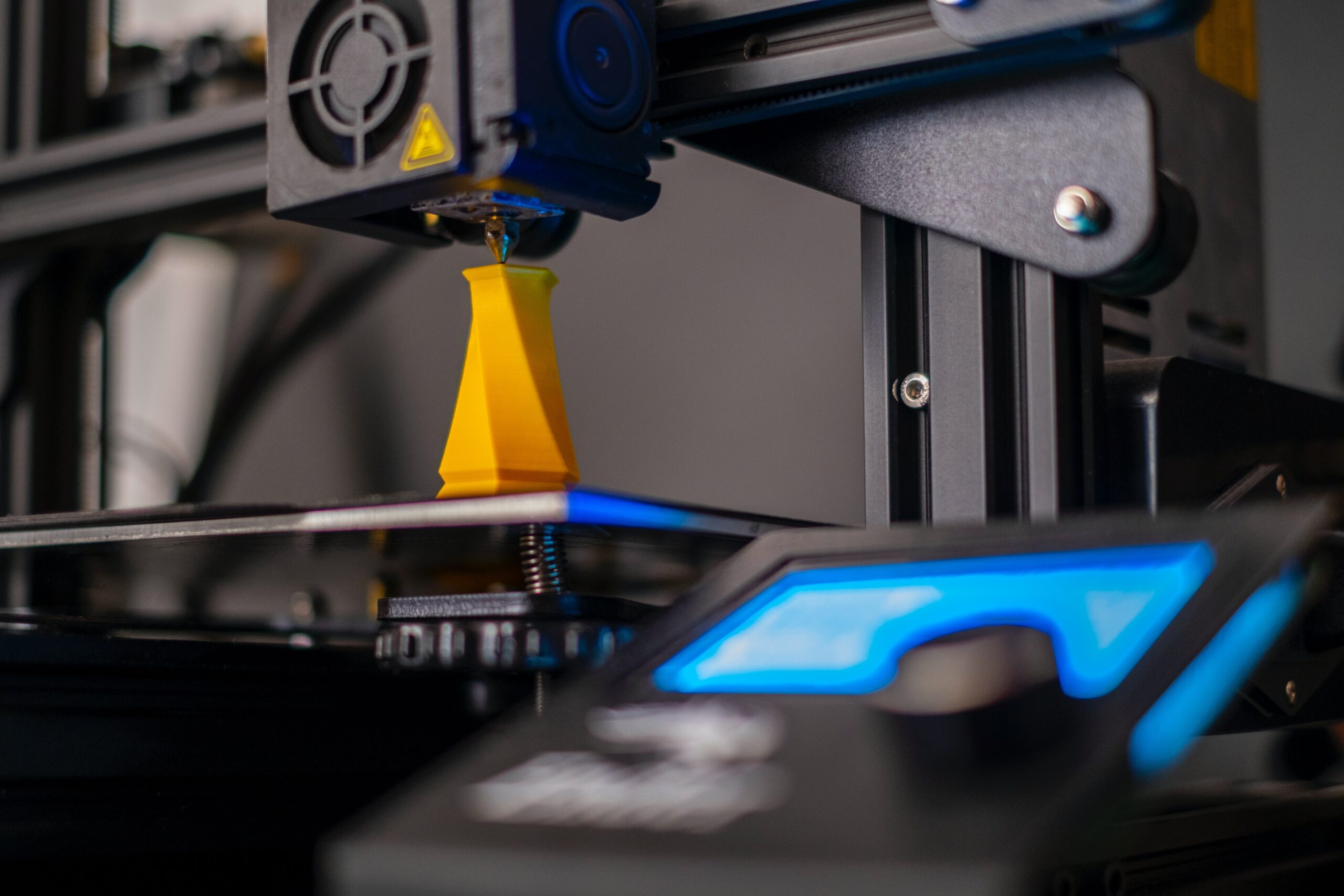

3. Printing

The 3D printer reads the sliced design and deposits material layer by layer. Various printing technologies exist, each with its own materials and techniques. Fused Deposition Modeling (FDM) melts and extrudes thermoplastic materials, while Stereolithography (SLA) uses lasers to cure liquid resin.

4. Curing or Solidifying

Some printers use lasers or ultraviolet (UV) light to cure or solidify the material, layer by layer. Others, like FDM printers, use heat to melt and fuse thermoplastic materials.

5. Cooling and Assembly

Once a layer is complete, it cools and hardens. The process repeats until the entire object is formed. Some printers can even produce fully assembled, moving parts in one go.

A Glimpse into the Future

As we unravel the layers of 3D printing’s past and present, one thing is clear: we stand on the precipice of a new era in creation and innovation. What lies ahead?

Mainstream Adoption:

3D printers could become household staples, used for everything from printing replacement parts to crafting customized home decor. Some experts predict that by 2030, 3D printers could be as common as microwaves.

Medical Marvels:

The field of medicine will witness ground-breaking developments. Expect 3D-printed prosthetics, implants, and even functional organs to become standard, revolutionizing patient care. In the next decade, we may see widespread use of 3D-printed medical devices and even simple drug formulations.

Sustainable Manufacturing:

3D printing will transform manufacturing into a sustainable enterprise. It will reduce waste and enable on-demand production, eliminating the need for extensive inventory and long-distance shipping. Over the next five years, expect more industries to adopt 3D printing for sustainable practices.

Education and Innovation:

Education will undergo a renaissance. Schools and universities will embrace 3D printing as a tool for teaching subjects across the curriculum. Within a decade, students will routinely use 3D printers to explore concepts in science, engineering, and the arts. It isn’t unlikely that 3D printing will become an essential part of your studies or even a subject on its own.

Space Odyssey:

One final frontier beckons with 3D printing leading the way. Astronauts on extended missions will use 3D printers to fabricate tools, replacement parts, and even habitats. Within the next few years, we can anticipate more frequent utilization of 3D printing in space exploration, there might even be 3D printing on Mars in the near future.

Final Thoughts

In the world of 3D printing, imagination knows no bounds. It’s a realm where dreams and designs become reality, where creativity knows no limits and the tangible and the digital converge in a symphony of innovation. While there is still a lot of potential, 3D printing has become a viable technology for many different industries and even for personal or educational use. Consider it one of the technologies that will shape our future, positively impacting economic growth, manufacturing efficiency and quality of life.

Sources and further reading:

Investopedia, “3D Printing: What It Is, How It Works, Examples”

PC Mag, “3D Printing: What You Need to Know”

TWI, “What Is 3D Printing? – Techology Definition and Types”

Builtin, “3D Printing”

Written with support from ChatGPT by OpenAI